TSSPL is a company, built to provide industrial applications such as structural engineering, instrumentation and electrical engineering with a healthy dose of creativity, and extensive technical knowledge. We provide quality services and solutions for Industrial Automation, Instrumentation, Electrical and Electronics related field.

Our engineers and technicians have extensive experience in most common PLC, SCADA, VFD and other automation equipments. If you plan to change, upgrade, troubleshoot your automation installation or have a completely new need, we can provide you with uninterrupted support from product selection to basic engineering, software development, commissioning and post-commissioning support.

We believe in providing ultimate satisfaction to our clients and our team of experts are always available to provide uninterrupted technical support and advice.

Work for Future Automation and Control

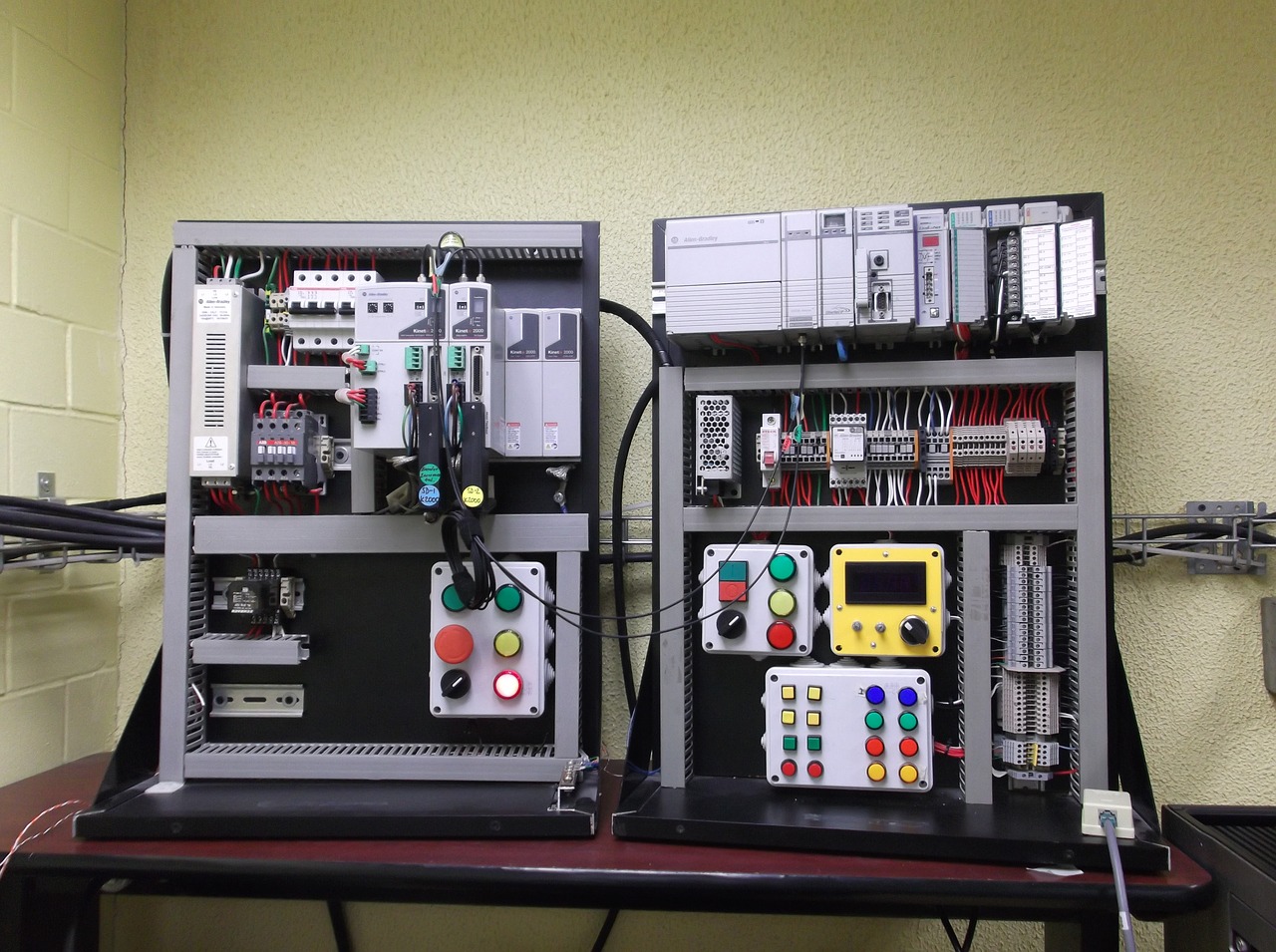

A programmable logic controller (PLC) is an industrial computer, combined with multi-disciplinary control solutions and connectivity portfolios focused on controllers and I / O, you can deliver systems in a smart, productive and secure integrated architecture isolated, process, motion and safety applications.

Our systems are designed to control the production process for assembly lines, machines, robotic devices, or any activity with high reliability, programming simplicity, and process error diagnosis. .

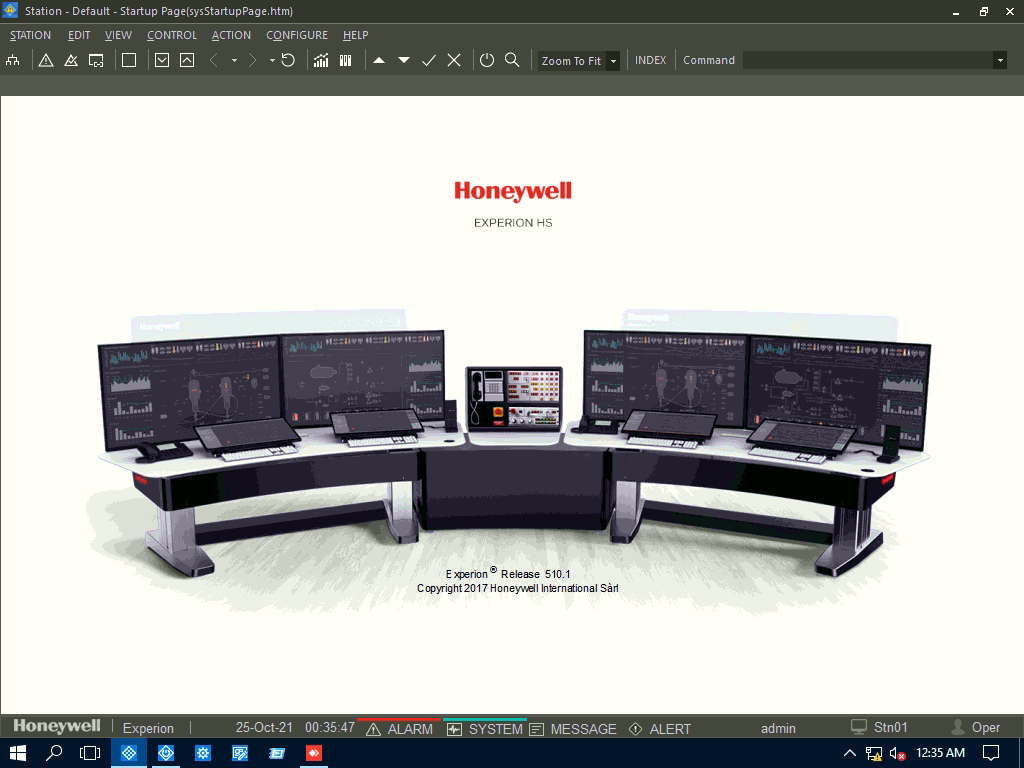

Supervisory control and data acquisition (SCADA) is a highly reliable supervisory control system architecture that visualize, monitor, gather, process real-time data and directly interact with devices such as sensors, valves, pumps, motors, and more through human-machine interface (HMI) software.

Our highly skilled experts support the complete SCADA value chain. We strive to be a the trusted partner from design, SCADA hardware production, software development, network design and solution installation to surveillance and maintenance.

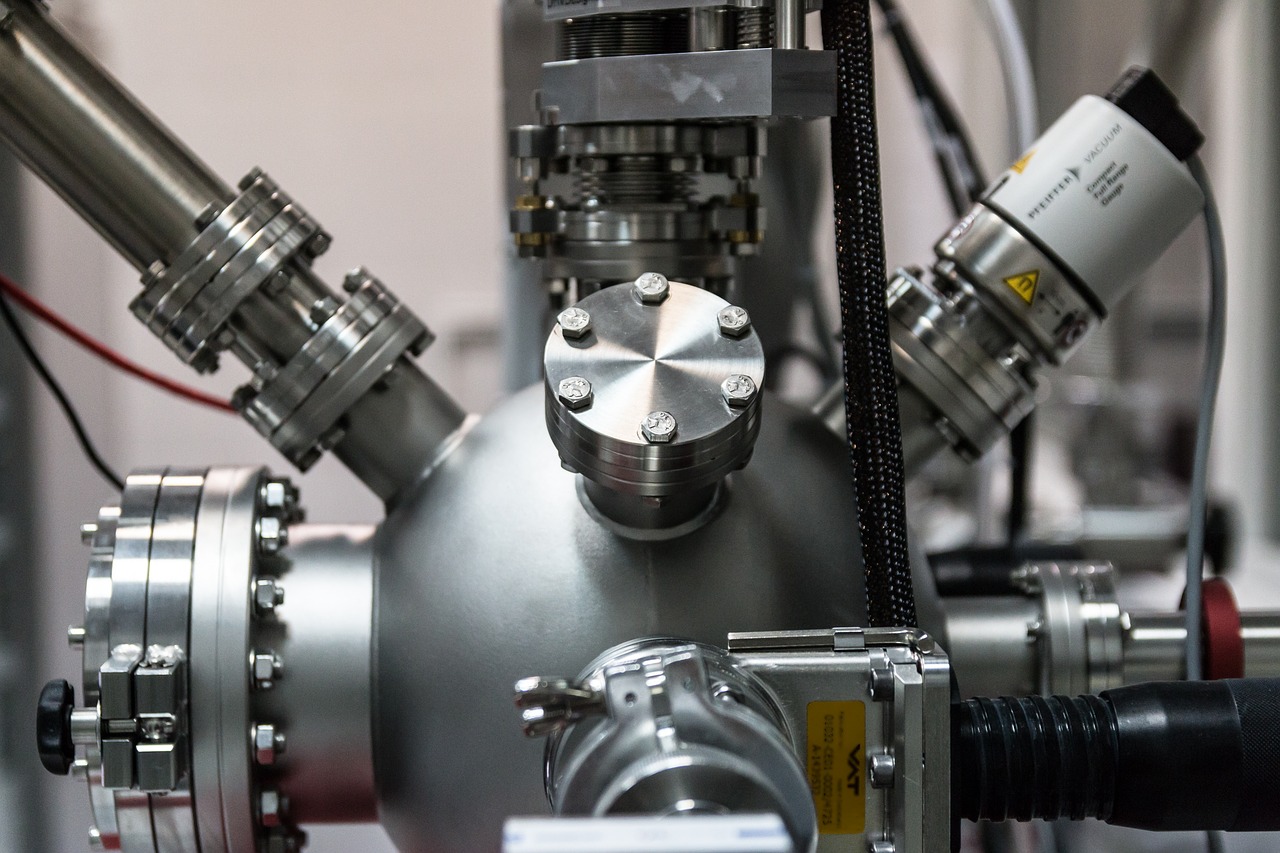

Distributed Control Systems (DCS) is a computerized control system for a process or plant consisting of a large number of control loops, with autonomous controllers distributed throughout the system, but there is central operator supervisory control.

DCS can be used to increase reliability and reduce installation costs by localizing control functions near the process center with remote monitoring and supervision.

DCS products, solutions, services for continuous or batch process industries, infrastructure, energy and utilities are delivered in collaborative control rooms.